Lith Corporation, founded in 1998 by a group of material science doctor from Tsinghua University, has now become the leading manufacturer of battery lab&production equipment. Lith Corporation have production factories in shenzhen and xiamen of China.This allows for the possibility of providing high quality and low-cost precision machines for lab&production equipment,including: roller press, film coater,mixer, high-temperature furnace, glove box,and complete set of equipment for research of rechargeable battery materials. Simple to operate, low cost and commitment to our customers is our priority.

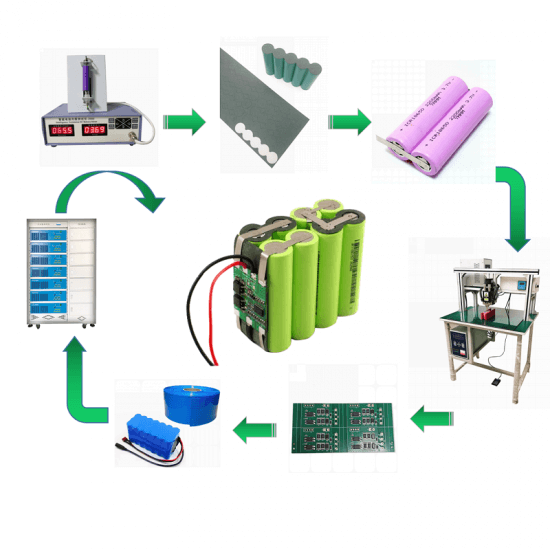

18650 Fabrication: A Comprehensive Guide

The 18650 cell is one of the most widely used cylindrical lithiumion battery formats, with dimensions of 18mm diameter and 65mm height. These cells are commonly found in consumer electronics, electric vehicles (EVs), energy storage systems, and portable devices due to their robust design, high energy density, and reliability.

Below is a detailed guide on the fabrication process for 18650 cells, including key steps, materials, equipment, and challenges.

●What Is an 18650 Cell?

An 18650 cell is a rechargeable lithiumion battery housed in a cylindrical metal can. It consists of:

Anode: Negative electrode, typically made of graphite or siliconbased materials.

Cathode: Positive electrode, commonly composed of lithium cobalt oxide (LiCoO₂), nickelmanganesecobalt (NMC), or nickelcobaltaluminum (NCA).

Electrolyte: A liquid medium containing lithium salts dissolved in organic solvents to facilitate ion transport.

Separator: A porous polymer film (e.g., polyethylene or polypropylene) that prevents direct contact between the anode and cathode while allowing ion flow.

Metal Can: Cylindrical metal casing (steel or aluminum) that houses the cell components.

Top Cap Assembly: Includes the positive terminal, safety features (e.g., pressuresensitive fuses), and insulating gaskets.

●Key Steps in 18650 Fabrication

1. Material Preparation

Slurry Mixing:

Combine active materials (e.g., LiCoO₂ for the cathode or graphite for the anode), conductive additives (e.g., carbon black), and binders (e.g., polyvinylidene fluoride [PVDF]) in a solvent (e.g., Nmethyl2pyrrolidone [NMP]) to create a homogeneous slurry.

Homogenization:

Use mixers or ultrasonic homogenizers to ensure uniform distribution of particles in the slurry.

2. Electrode Coating and Drying

Coating:

Apply the slurry onto current collector foils (aluminum for the cathode, copper for the anode) using techniques like doctor blade coating or slot die coating.

Drying:

Remove the solvent by drying the coated foils in a vacuum oven at elevated temperatures (e.g., 80–120°C).

3. Cutting and Tab Welding

Cutting:

Cut the coated electrodes into strips with predefined dimensions using a die cutter.

Tab Welding:

Attach metallic tabs (usually nickel or aluminum) to the electrodes for electrical connection using ultrasonic welding or resistance welding.

4. Winding

Wind the cathode, separator, and anode together into a jellyroll structure. Precision winding ensures even layer alignment and prevents misalignment.

5. Insertion into Metal Can

Insert the wound jellyroll into a cylindrical metal can. The bottom of the can acts as the negative terminal.

6. Top Cap Assembly

Place the top cap assembly, which includes the positive terminal, safety features (e.g., pressuresensitive fuses), and insulating gaskets, onto the open end of the can.

7. Electrolyte Injection

Inject the electrolyte solution into the can through a small opening in the top cap. The electrolyte wets the electrodes and separator.

8. Sealing

Seal the top cap to the metal can using laser welding or crimping to create a hermetic seal, ensuring no leakage occurs.

9. Formation and Testing

Formation Cycle:

Subject the assembled 18650 cell to a formation cycle to activate the battery and form a stable solid electrolyte interphase (SEI) layer on the anode.

Performance Testing:

Evaluate the cell's capacity, voltage profile, cycling stability, internal resistance, and other key parameters using electrochemical testing equipment.

10. Quality Control and Packaging

Inspect finished cells for defects such as swelling, leaks, or short circuits using visual inspection, Xray imaging, or impedance measurement systems.

Package the cells for shipment.

●Equipment Used in 18650 Fabrication

1. Slurry Mixer:

Combines active materials, binders, and solvents to create a uniform slurry.

Example: Planetary mixer or dualshaft mixer.

2. Coater:

Applies the slurry uniformly onto current collector foils.

Example: Slot die coater or doctor blade coater.

3. Drying Oven:

Removes solvents from the coated electrodes under controlled conditions.

Example: Convection ovens or vacuum ovens.

4. Die Cutter:

Cuts the coated electrodes into strips with predefined dimensions.

Example: Rotary die cutter or laser cutter.

5. Tab Welder:

Attaches metallic tabs to the electrodes using ultrasonic welding or resistance welding.

Example: Ultrasonic tab welder or laser tab welder.

6. Winding Machine:

Winds the cathode, separator, and anode into a jellyroll structure.

Example: Fully automated winding machines with tension control and alignment systems.

7. Insertion Machine:

Inserts the wound jellyroll into the cylindrical metal can.

Example: Automated insertion machines with precision alignment.

8. Top Cap Assembler:

Places the top cap assembly onto the can.

Example: Semiautomated or fully automated top cap assembly machines.

9. Electrolyte Injector:

Injects the electrolyte solution into the can under vacuum conditions.

Example: Highprecision electrolyte injection systems with flow control.

10. Laser Welder:

Seals the top cap to the metal can using laser welding.

Example: Fiber laser welder or pulsed Nd:YAG laser welder.

11. Crimping Machine:

Alternatively, seals the top cap using crimping for lowercost applications.

Example: Hydraulic or pneumatic crimping machines.

12. Formation Chamber:

Activates the battery and forms the SEI layer during the formation cycle.

Example: Temperaturecontrolled formation chambers with programmable charge/discharge cycles.

13. Electrochemical Tester:

Evaluates the cell's performance parameters.

Example: Multichannel battery testers with data logging capabilities.

14. Inspection System:

Detects defects such as swelling, leaks, or short circuits.

Example: Visual inspection systems, Xray imaging, or impedance measurement systems.

15. Packaging Equipment:

Packages the finished cells for shipment.

Example: Automatic labeling and boxing machines.

Battery Pack Machine

●Applications of 18650 Cells

1. Electric Vehicles (EVs):

Battery packs for hybrid and fully electric vehicles, including Tesla's early models that used 18650 cells extensively.

2. Consumer Electronics:

Laptops, flashlights, power banks, and other portable devices.

3. Energy Storage Systems (ESS):

Gridscale energy storage and backup power solutions.

4. Medical Devices:

Portable diagnostic tools and certain implantable devices.

5. Industrial Applications:

Robotics, drones, and other highpowerdensity applications.

●Advantages of 18650 Cells

1. Robust Design:

Metal casing provides excellent structural integrity and protection against external damage.

2. High Production Efficiency:

Standardized designs allow for mass production at lower costs.

3. Excellent Thermal Management:

The cylindrical shape facilitates efficient heat dissipation.

4. Proven Reliability:

Widely used and tested in various industries, ensuring longterm reliability.

5. Safety Features:

Integrated safety mechanisms like pressure relief vents reduce the risk of thermal runaway.

●Challenges in 18650 Fabrication

1. Internal Resistance:

Higher internal resistance compared to pouch or prismatic cells due to the cylindrical geometry.

2. Weight:

The metal casing adds weight, making them less suitable for weightsensitive applications.

3. Space Utilization:

Less efficient use of space compared to pouch cells, limiting their application in compact devices.

4. Swelling Risk:

Gas generation during operation can cause swelling, reducing performance and lifespan.

5. Cost:

Metal casing and additional safety features increase material costs.

●Safety Considerations

1. Handling Lithium Metal:

Lithium is highly reactive and must be handled in a dry, oxygenfree environment.

2. Electrolyte Exposure:

Avoid skin and eye contact with electrolyte solutions, as they may be toxic or corrosive.

3. Proper Disposal:

Dispose of waste materials, such as used electrodes and electrolytes, according to environmental regulations.

●Future Trends in 18650 Fabrication

1. Advanced Materials:

Incorporation of novel materials like silicon anodes, sulfur cathodes, or solidstate electrolytes for enhanced performance.

2. Automation:

Increased automation in production lines to improve throughput and reduce costs.

3. Sustainability:

Focus on environmentally friendly materials and recycling processes to minimize ecological impact.

4. Integration with Other Technologies:

Combining 18650 cells with supercapacitors or fuel cells for hybrid energy storage systems.

5. Larger Formats:

Development of larger formats like the 21700 and 4680 cells for improved energy density and reduced cost per kWh in EVs.

●Conclusion

The fabrication of 18650 cells involves precise preparation of electrode materials, careful assembly of components, and rigorous testing to ensure reliability and performance. By understanding the steps, equipment, and challenges involved, manufacturers can optimize their designs for specific applications. As advancements in materials and fabrication techniques continue, 18650 cells will remain a critical component of modern energy storage technology.

What aspect of 18650 fabrication excites you most? Share your thoughts below! Together, let’s explore how these innovative batteries are shaping the future of energy storage.

+86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588